Back when I heard of it last year I immediately wanted to try it. Then I heard the name again when someone was describing the feel of the Studio by Sculpey clay.(Of course you know I heard of it in a forum somewhere) Back to the subject, I bought a pack of it with another order because I wanted to try it. Well, I’ll let you be the judge, after I tell you that it was soft enough out of the pack to condition by hand, really, by HAND ! But the thing it, it wasn’t the sticky, smooshy, doughy, clay we normally put up with. Wait!! That’s not the best part, the BLACK has some kind of mica or really fine glitter, either way I LOVE it. I don’t know if the other colors have it or not, but I plan on finding out 🙂 } Dare I say it ?} It makes me want to give up my Kato !!!!!??????!!!!! Oh no, where’s my couch. I feel faint! Oh, the funny thing is, I have even tried the Studio by Sculpey clay, yet 🙂 Click on the pictures to see them a little better.

Back when I heard of it last year I immediately wanted to try it. Then I heard the name again when someone was describing the feel of the Studio by Sculpey clay.(Of course you know I heard of it in a forum somewhere) Back to the subject, I bought a pack of it with another order because I wanted to try it. Well, I’ll let you be the judge, after I tell you that it was soft enough out of the pack to condition by hand, really, by HAND ! But the thing it, it wasn’t the sticky, smooshy, doughy, clay we normally put up with. Wait!! That’s not the best part, the BLACK has some kind of mica or really fine glitter, either way I LOVE it. I don’t know if the other colors have it or not, but I plan on finding out 🙂 } Dare I say it ?} It makes me want to give up my Kato !!!!!??????!!!!! Oh no, where’s my couch. I feel faint! Oh, the funny thing is, I have even tried the Studio by Sculpey clay, yet 🙂 Click on the pictures to see them a little better.

Do a quick GOOGLE on Cernit, a lot of vendors carry it. Here’s a blurb from one vendor

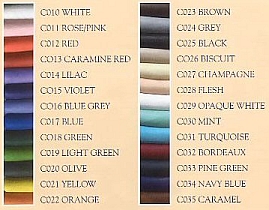

Cernit Polymer clay is soft and easy to work, right out of the package. No other material will give you the translucence you get with Cernit no. 1 and its tensile strength lets you work with the thinnest imaginable pieces. Cernit no. 1 cures to a porcelain-like finish while Cernit Neon-Light is luminescent in bright, day-glo colors and Cernit Glamour colors are pearlescents. Many shades of color available and all able to be mixed to create still other tones.

I will tell you this, it seems to me that the prices are a little higher than the other clays, but, you get what you pay for, as my granny used to say.

http://www.gigagraphica.com/poly/polyclay.html – This is a website that has some more info on it

See ya’ll next time 🙂

Cernit was probably the third clay brand I worked with and it spoiled me rotten, lol. Like most people probably did, I started with Sculpey III and quickly moved on to Fimo and then Fimo soft. Once I moved to try Cernit however, I never moved on. I suppose I really need to try Kato and the Studio clay but my hands love the feel of Cernit too much. I will say that the standard colors do tend to darken A LOT once baked so most all of those get mixed with white (buy the big block of white, you’ll need it) but other than that I have zero complaints about this polyclay brand. BTW, I also adore the porcelain-like finish. 😀

really? I have a box of cernit and to me its REALLY hard to mold. maybe it’d a different version or something but it hurts my hand and I have a really different opinion!

Hey Sophia! That post is from a few years ago by a previous blogger. I’m with you, I found Cernit to be harder to work with than Premo. I suppose it’s just a matter of what you’re used to!

Cernit cures hard, but still pretty flexible like fimo classic and kato. Cernit is great for thinner more delicate pieces. l tried the translucent, which is like super slimy . l leached it and it has messed up the consistency of the clay so l won’t be doing that again.

l have another block in blue and that was so easy to condition, shape and use. Like premo l get hairline cracks more easily when curing in beads so for me right now cernit is a mixed bag. The color seriously darkens after curing so that made me a bit anxious about buying more it.

I usually buy Cernit, the only fail is how hard it is, usually red is very hard and black is impossible… i havent come across very gewy squishy sticky ones, i like Fimo but the transparent ones are a bit too soft.

It is an excellent clay for miniatures. I have sculpted some small busts having hights of approx. 2 inches. It keeps even the smallest details (eyes, ears, lips, hair, wrinkles etc.) and you can cut very easily when you have to adjust the face of your bust. I worked for some complicated busts and some times I had to work two weeks for a project and it kept the same quality. One thing very important! I have an improvized oven made by me on my gas burner. This clay is excelent after it is baked. It is shiny a little bit. It seems to have some life inside. Follow the instructions and you will have an excellent bust. I prefer this clay.

I find Cernit to be really hard to work with.

It takes a long time to condition, and then when you try to roll it it’s still very hard, and it get’s crumbly. I absolutely cannot handle the crumbleness! It just rips apart no matter how many times I tried to. Since it’s so rough, imperfections are hard to smooth out.

The good side is, that it doesn’t leave fingerprints.

Overall : I would not recommend Cernit to anyone. I bought 10 packs and now I just don’t know how to get rid of them.

Hi Laura!

This post was from a little bit ago – I haven’t had the chance to really play with Cernit but I found the same as you: that it was difficult to condition. And I have an easily available difficult to condition clay already!